Tailored products

Oscillators

In the demanding conditions of the paper and board industry, every tool and machine component matters.

Tailored products

In the demanding conditions of the paper and board industry, every tool and machine component matters.

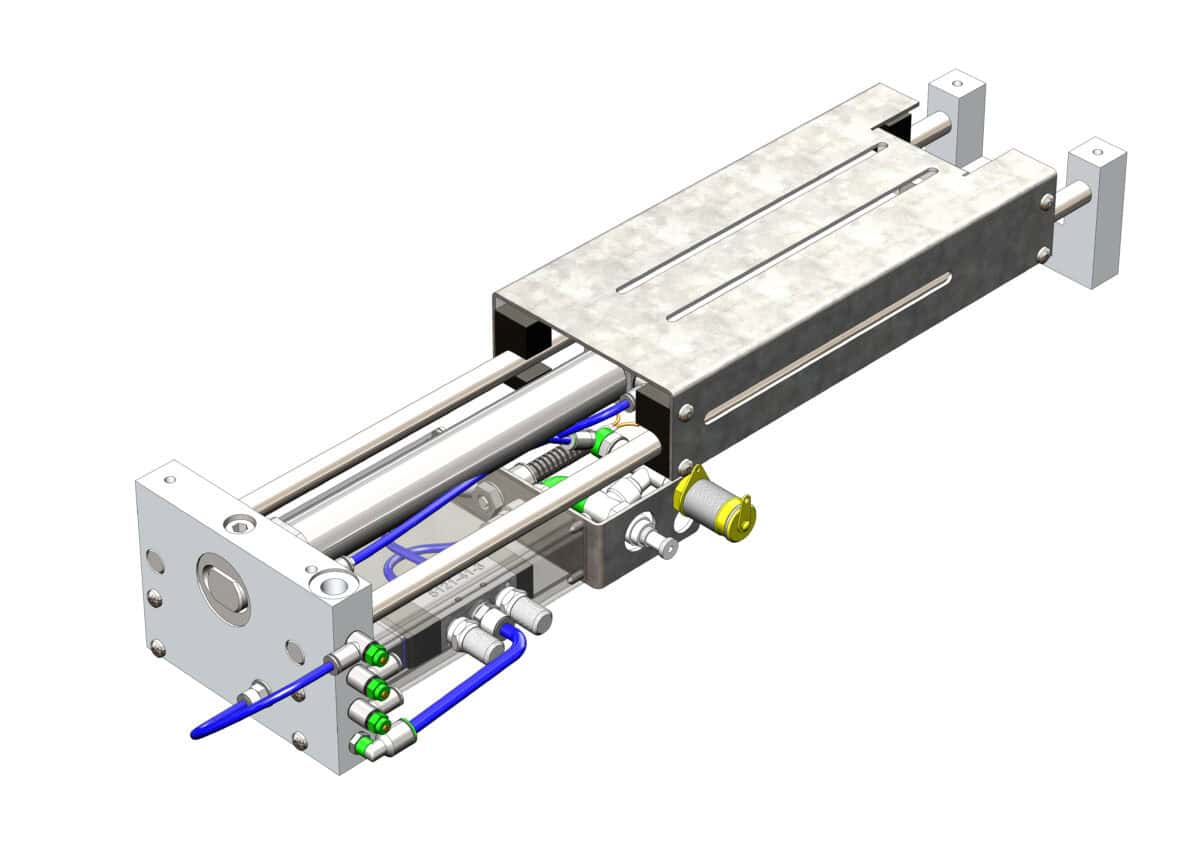

Oscillation refers to a back-and-forth motion that can be utilized in various functions — for example, to ensure the smooth movement of a doctor blade beam in paper and board machines. This helps the blade wear evenly and keeps the roll clean from pulp. In collaboration with leading paper and board machine manufacturers, we have developed a superior range of oscillators that perform reliably in demanding conditions.

The oscillators feature a compact structure that integrates both the cylinder and the valve controlling its movement. Each unit is designed, engineered, and manufactured by the skilled hands of Pimatic’s dedicated professionals.

Compact pneumatic doctor blade oscillator for dry and wet end applications.

Benefits:

Pneumatic oscillating actuator with integrated controls.

Benefits:

Cases — Valmet

Valmet paper machines aim to provide a high quality and performance for the pulp, paper, board and tissue mills around the world. As part of this, the smooth web runnability is ensured through a range of efficient fabric guide solutions – one among them is the pneumatic guide cylinder from Pimatic.

Tutustu Solutions for Paper Industry -esitteeseen